SulfiLogger™ H2S Sensor

SulfiLogger™ H2S Sensor

Territory Instruments provides SulfiLogger™ H2S sensors for continuous real-time sulfide monitoring in air, water, gas, and wastewater networks. Ensure regulatory compliance, reduce corrosion risks, and optimise chemical dosing with advanced analytics and rugged field-ready design.

Browse Items

SulfiLogger™ S1/X1-1020 H2S Sensor – Continuous Monitoring for Wastewater

As the authorized distributor for SulfiLogger™ in Australia, we offer the S1/X1-1020 sensor for continuous hydrogen sulfide (H2S) monitoring in harsh wastewater and sewer environments. Designed for both permanent and portable use, this sensor delivers real-time data via 4-20mA or cloud connectivity using the PowerCom Box. Pinpoint hotspots, optimize chemical dosing, and gain reliable insights. Get a quote today!

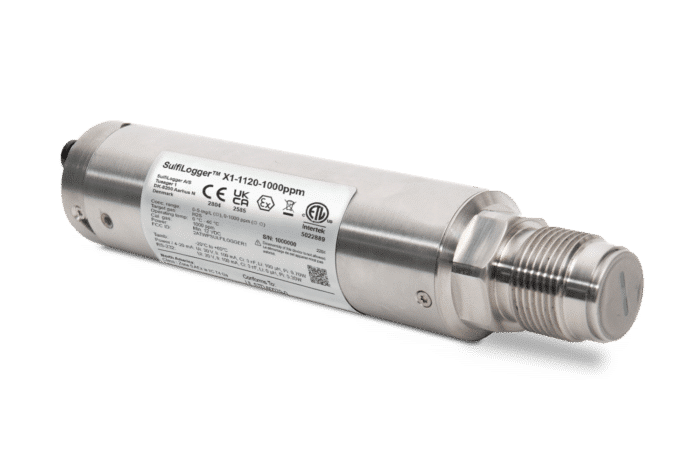

SulfiLogger™ S1/X1-1120 H2S Sensor – Pressurized Wastewater & Biogas Monitoring

As the authorized distributor for SulfiLogger™ in Australia, we offer the S1/X1-1120 sensor for continuous H2S measurement in pressurized wastewater and wet biogas environments. Ideal for optimizing desulphurization, preventing corrosion, and maintaining safety compliance, it integrates easily into SCADA/PLC systems and supports cloud connectivity via PowerCom Box. Get a quote today!

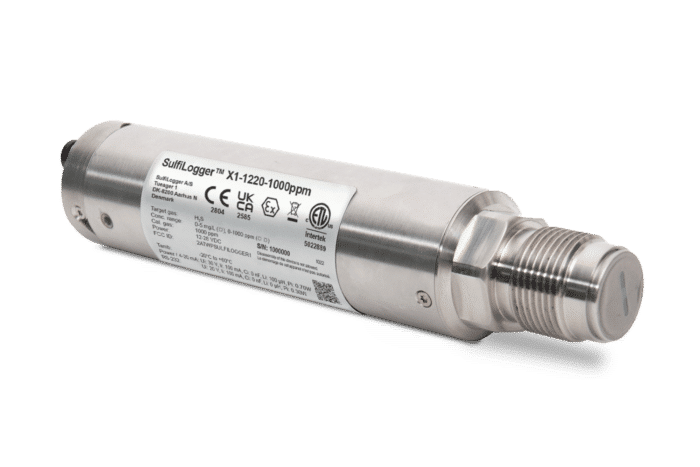

SulfiLogger™ X1-1220 H2S Sensor – Natural Gas & Process Water Monitoring

As the authorized SulfiLogger™ distributor in Australia, we supply the X1-1220 sensor for real-time H2S measurement in untreated natural gas and pressurized process water. Designed for harsh offshore and onshore environments, it features Ex certification (Zone 0 / Class 1 Div 1) and corrosion-resistant stainless steel housing. Ideal for separator monitoring, corrosion prevention, and desulphurization optimization. Get a quote today!

SulfiLogger™ H2S Sensor

Territory Instruments provides SulfiLogger™ H2S sensors for continuous real-time sulfide monitoring in air, water, gas, and wastewater networks. Ensure regulatory compliance, reduce corrosion risks, and optimise chemical dosing with advanced analytics and rugged field-ready design.

Browse Items

SulfiLogger™ S1/X1-1020 H2S Sensor – Continuous Monitoring for Wastewater

As the authorized distributor for SulfiLogger™ in Australia, we offer the S1/X1-1020 sensor for continuous hydrogen sulfide (H2S) monitoring in harsh wastewater and sewer environments. Designed for both permanent and portable use, this sensor delivers real-time data via 4-20mA or cloud connectivity using the PowerCom Box. Pinpoint hotspots, optimize chemical dosing, and gain reliable insights. Get a quote today!

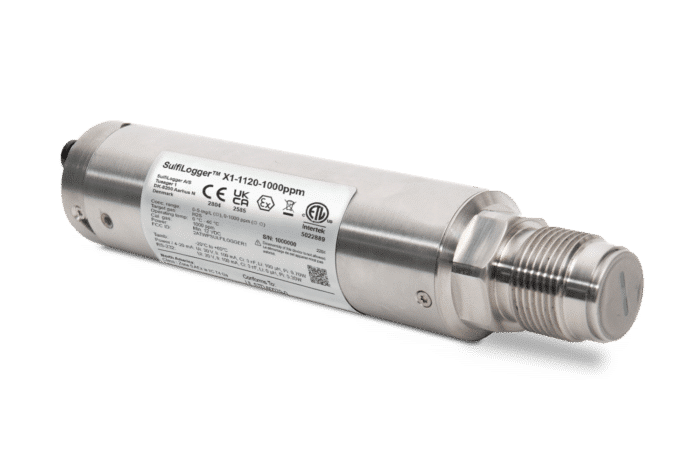

SulfiLogger™ S1/X1-1120 H2S Sensor – Pressurized Wastewater & Biogas Monitoring

As the authorized distributor for SulfiLogger™ in Australia, we offer the S1/X1-1120 sensor for continuous H2S measurement in pressurized wastewater and wet biogas environments. Ideal for optimizing desulphurization, preventing corrosion, and maintaining safety compliance, it integrates easily into SCADA/PLC systems and supports cloud connectivity via PowerCom Box. Get a quote today!

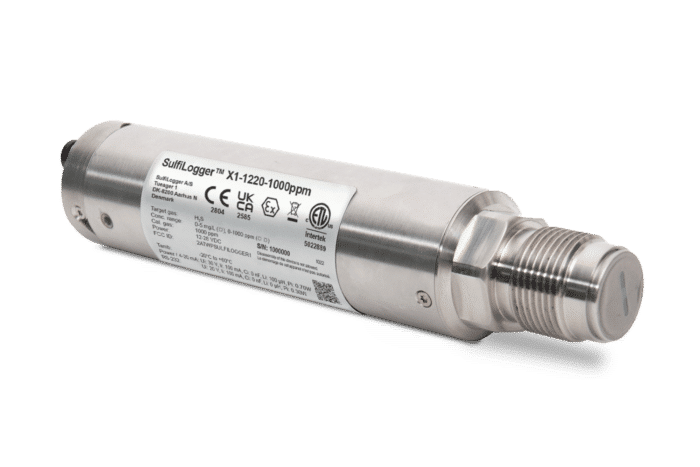

SulfiLogger™ X1-1220 H2S Sensor – Natural Gas & Process Water Monitoring

As the authorized SulfiLogger™ distributor in Australia, we supply the X1-1220 sensor for real-time H2S measurement in untreated natural gas and pressurized process water. Designed for harsh offshore and onshore environments, it features Ex certification (Zone 0 / Class 1 Div 1) and corrosion-resistant stainless steel housing. Ideal for separator monitoring, corrosion prevention, and desulphurization optimization. Get a quote today!